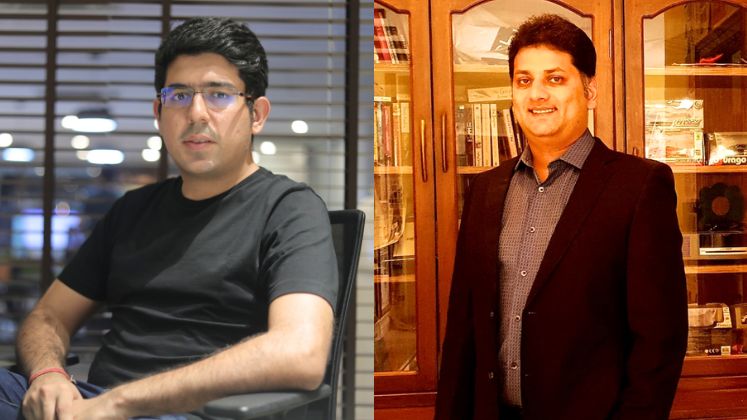

Sidhant Keshwani, Founder and CEO, Libas

Every apparel mannequin needs a clear sourcing method. The choice between native and world sourcing consists of components like cost-effectiveness, present chain evaluation, top quality assurance and market demand analysis.

Native sourcing offers quick value monetary financial savings by reducing transportation payments and tariffs and mitigating foreign exchange fluctuation risks. It moreover ensures shorter present chains, leading to lower inventory costs and elevated flexibility in response to market requires.

Native sourcing is particularly advantageous the place top quality administration, customisation and quick turnaround events are necessary. It permits less complicated entry for frequent top quality inspections and quick scenario choice. As an illustration, many vogue houses like Benetton have started sourcing nearer to residence. In 2022, Benetton boosted its manufacturing in Europe, West Asia and North Africa, shifting manufacturing out of Bangladesh and Vietnam. Equally, a study confirmed that Swedish textile and apparel shoppers plan to increase sourcing in Europe whereas reducing or altering sourcing in Asia.

For Indian apparel producers, native sourcing can current necessary value monetary financial savings as compared with worldwide sourcing. By sourcing regionally, producers can avoid import duties of as a lot as 40 per cent on apparel merchandise, leading to spherical 20 per cent monetary financial savings on manufacturing costs.

I agree that it’s not attainable for the entire producers to provide 100 per cent regionally. Subsequently when considering world sourcing, Indian producers ought to weigh in numerous components. As an example, China offers aggressive pricing and fast turnaround events nevertheless faces rising labour costs and commerce tensions. Bangladesh has the underside labour costs nevertheless struggles with top quality consistency and longer lead events. Vietnam gives a steadiness with aggressive labour costs, high-quality manufacturing, versatile minimal order parts and bettering logistics. Nonetheless, it’s necessary to undertake a nuanced technique.

As an example, a vogue mannequin primarily based in India might uncover primarily essentially the most cost-effective supplier of elastics in Vietnam. However, to completely capitalise on value monetary financial savings, the supplier might go for cheaper transportation equal to barges, leading to extended provide events besides expedited transport is paid for. In such a scenario, the mannequin might choose the Vietnamese supplier for regular orders nevertheless devise a contingency plan for urgent duties, most likely sustaining a stockpile of provides. Alternatively, the mannequin might go for barely pricier elastics from one different supplier. Each mannequin ought to think about its priorities and resolve whether or not or not value or tempo takes precedence in sourcing provides. This decision-making course of is unique to each entity, regardless of dimension and completely completely different firms can have distinct models of requirements.

At current’s customers price sustainability, ethical manufacturing and supply chain transparency. This drives us to provide 100 per cent of our raw provides domestically. This system helps Libas in the long term by guaranteeing that every one sourcing and manufacturing processes are streamlined all through the nation, essential to larger administration over top quality and consistency of provides.

For producers considering world enlargement, native sourcing offers a particular profit. In right now’s world financial system, realizing the origins of our raw provides is solely the beginning line. We should always moreover make sure that our provides are responsibly sourced, a requirement enforced by regulators and anticipated by customers. This requires thorough due diligence on every supplies and accent we use.

Many countries are literally implementing traceability authorized pointers. India too is predicted to introduce comparable legal guidelines inside the foreseeable future, aligning with world tendencies in the direction of accountable sourcing and manufacturing practices. This raises important questions: Have been the cotton and completely different provides ethically harvested? Have been truthful labour conditions maintained all through material manufacturing? If we won’t current satisfactory options to regulatory inquiries and consumer points about sourcing transparency, our means to market merchandise in areas with tightening legal guidelines may be compromised.

Native sourcing shouldn’t be solely about effectivity however as well as about investing in the best way ahead for the Indian garment enterprise. By relying on native suppliers, firms strengthen the house financial system. In response to a FICCI-Wazir Advisors report, the Indian textile and apparel market was valued at roughly US $ 165 billion in 2022, with the house market accounting for US $ 125 billion and exports contributing US $ 40 billion. With a optimistic long-term outlook, the market dimension is projected to develop at a compound annual improvement cost (CAGR) of 10 per cent, reaching US $ 350 billion by 2030. This interprets to necessary employment alternate options, fostering monetary improvement and bettering livelihoods inside native communities.

About: Libas is an omnichannel mannequin that sells fast vogue Indian standard apparel for women all through every offline and on-line channels. The mannequin claims to cross Rs. 500 crore earnings mark in FY ’24.

Navin S Rao, Co-founder, The Kaftan Agency

At current’s customers price sustainability, ethical manufacturing and supply chain transparency. This drives us to provide 100 per cent of our raw provides domestically. This system helps Libas in the long term by guaranteeing that every one sourcing and manufacturing processes are streamlined all through the nation, essential to larger administration over top quality and consistency of provides.

At Kaftan, we regularly encounter distinctive material prints or specific elasticities that aren’t merely found regionally. In such circumstances, we take a look at the manufacturing course of of these supplies and ponder, ‘This may enhance the comfort for our shoppers, so let’s experiment’. From a developmental angle, we assess these distinctive provides retrospectively. If, post-production, they match our mannequin and top quality necessities, we switch forward with sourcing them. As an illustration, in our earlier summer season assortment, we procured some supplies from China. We discovered that the elasticity and luxurious of that material would delight our customers.

However, given that start, we’ve prioritised native sourcing, primarily for its cost-effectiveness. Initially, procuring large parts of fabric was impractical. Moreover, dealing with import duties and logistics would’ve strained our sources.

Moreover, rising the availability chain and establishing relationships with distributors in a model new nation takes time. Each stage have to be evaluated accurately to avoid risks. Initially, one essential hurdle is the small order sizes of some producers. With solely a handful of retailers, we lack substantial order volumes and worldwide producers are typically unwilling to accommodate small orders. In distinction, Indian producers provide flexibility in minimal order parts, allowing us to order anyplace from 500 to 50,000 objects, catering to our specific needs.

Moreover, India has an unlimited market for sourcing. As an example, states like Gujarat can produce lakhs of metres of fabric with fairly a couple of decisions obtainable. India moreover has over a thousand GOTS (World Pure Textile Regular)-certified factories and loads of completely different licensed objects dedicated to ethical and sustainable manufacturing, providing versatile manufacturing decisions. Raw provides from India moreover tend to provide additional regular pricing, with a lot much less variation.

That’s why, even worldwide producers are rising their sourcing from India. As an example, France-based menswear mannequin Celio plans to increase its sourcing from India by 5 events from 4 per cent at present to twenty per cent over the approaching two years. World life-style producers equal to Patagonia are utilising regenerative pure cotton fields in India. Moreover, essential vogue retailers equal to Zara, Gap, Levi’s, Mango, Marks & Spencer and Tommy Hilfiger have moreover established manufacturing operations in India.

Though, no mannequin can determine to native sourcing indefinitely. All of it boils all the best way right down to how the market evolves and the relevance of the obtainable supplies. Moreover, it’s true that India has its limitations. Whereas we excel in cotton and pure supplies, our infrastructure, funding and R&D in high-quality MMF (Man-Made Fibres) are lacking. This often leads us to rely upon imports from China for these provides. Bangladesh and Vietnam are typically hottest for accomplished merchandise because of their superior infrastructure.

Specific yarns equal to Bi-shrinkage yarns are moreover not accessible regionally and are imported from China. This poses an issue, considerably for producers in womenswear, as they often wrestle with native sourcing and resort to importing of high-end yarns.

However, for producers specialising in menswear equal to denim, India and Bangladesh current ample decisions and alternate options for sourcing provides.

About: The Kaftan Agency, based mostly in 2016 by Prakruti Gupta Rao and Navin Rao, gives quite a lot of

loungewear and kaftans. On the market on essential e-commerce platforms, the company has seen 5x improvement inside the

earlier two years.