The fashion enterprise’s enormous waste disadvantage is driving governments the world over to set daring recycling targets. Nonetheless, recycling textiles is a complicated course of and technical choices are nonetheless of their early phases.

NGOs warn that the precise concern is overproduction and that technological enhancements may merely current a facade for producers to proceed producing billions of newest clothes.

Nonetheless, whatever the complexities, the stress to impress large-scale recycling is intensifying. In response to this, producers wish to attain extreme ranges of recycling at an unprecedented tempo or else face giant fines.

Quite a few progressive approaches are being explored to cope with the challenges of textile recycling. Whereas many couldn’t succeed, listed below are some current contenders that illustrate the numerous strategies being employed.

The fashion enterprise faces necessary stress to undertake environment friendly recycling practices swiftly. Whereas over-production stays an important concern, these rising utilized sciences present promising choices to cut back waste and enhance sustainability.

The success of these enhancements could play an important perform in meeting the daring recycling targets set by governments and mitigating the environmental have an effect on of the fashion enterprise.

MycoWorks: Mushroom Leather-based-based

MycoWorks is revolutionising the luxurious provides market by cultivating mycelium, the muse development of fungi, to create a cloth that rivals standard leather-based. Iconic producers akin to Hermes and Widespread Motors have already adopted this progressive ‘mushroom leather-based’ for his or her high-end luxurious merchandise, along with automotive interiors.

The manufacturing course of for MycoWorks’ mycelium-based leather-based is notably sustainable, requiring solely sawdust as raw supplies and the facility consumption is minimal since mycelium doesn’t require light with a objective to develop and utilises little or no water.

In distinction to many rising biomaterials companies that face challenges in scaling their operations, MycoWorks has effectively overcome these hurdles owing to the unimaginable product choices it affords. It proudly claims to be the first biomaterials agency to inaugurate a full-scale manufacturing facility. Located in South Carolina, this manufacturing unit began its operations with an preliminary harvest of 1,000 sheets of mycelium leather-based in January.

Circ: Unblending clothes

The fashion and apparel enterprise has prolonged been posed with the issue of recycling blended supplies owing to their blended supplies composition. Circ, a US-based agency, has developed an progressive chemical reply to kind out this disadvantage, significantly concentrating on polycotton, basically essentially the most prevalent fabric combine.

Circ’s hydrothermal course of efficiently liquefies polyester, separating it from cotton fibres. This allows every provides to be recycled into new fibres, promoting a further sustainable fashion enterprise.

In a notable utility of this experience, retail giant Zara built-in Circ’s recycled fibres proper into a garments line that was launched in April this 12 months.

Circ’s hydrothermal course of efficiently liquefies polyester, separating it from cotton fibres. This allows every provides to be recycled into new fibres, promoting a further sustainable fashion enterprise.

SuperCircle: Accumulating and sorting

The world faces necessary challenges in gathering and sorting large volumes of earlier clothes, which ought to keep clear and separate from completely different waste. SuperCircle addresses this concern by integrating provide companies, warehouses and monitoring strategies to streamline and in the reduction of the costs of the recycling course of.

The company objectives to shift public attitudes by offering in-store drop-off bins, free transport labels and completely different incentives to encourage recycling. “We would like ease, consolation and incentives for patrons so that after they’re executed with an merchandise, the very very first thing they assume is end-of-life recycling,” Stuart Ahlum, Co-founder of SuperCircle said. Presently, SuperCircle manages all recycling logistics for quite a few companies and sectors, along with Uniqlo North America.

SuperCircle objectives to shift public angle by offering in-store drop-off bins, free transport labels and completely different incentives to encourage recycling.

Saentis Textiles: In-house recycling

Saentis Textiles has addressed the quite a few drawback in textile recycling with its patented machine that recycles cotton whereas preserving fibre top quality, enabling the manufacturing of newest high-quality textiles.

Its recycled cotton is already utilized by distinguished producers akin to IKEA, Patagonia and Tommy Hilfiger. Now, Saentis Textiles is selling this machine to textile companies, letting them put in it straight of their factories. This permits on-the-spot recycling of cut-offs and scraps, further streamlining the recycling course of.

This not solely benefits the environment however moreover helps companies meet sustainability targets and regulatory requirements since in-house recycling contributes to a spherical monetary system model, the place provides are often reused, lowering the demand for virgin sources and minimising the environmental have an effect on.

Saentis Textiles holds a patent for its recycling machine, showcasing its innovation and administration in textile recycling experience.

Unspun: 3D weaving machine

Unspun claims to have developed the world’s first 3D weaving machine, which could create a custom-sized pair of jeans straight from yarn in beneath 10 minutes. The machine is designed in a technique that it’d produce jeans tailored to explicit particular person physique measurements, guaranteeing a really perfect match.

By using solely the required amount of yarn for each merchandise, the tactic reduces supplies waste significantly. This diploma of customisation helps in the reduction of the number of ill-fitting clothes that often end up as waste in landfills.

Presently, Unspun is developing its first micro-factory in Oakland, California to disclose this concept to the world. This progressive machine has the potential to take away the need for producers to handle large inventories, thereby lowering waste and transportation costs dramatically.

Cetia: Preparing earlier clothes

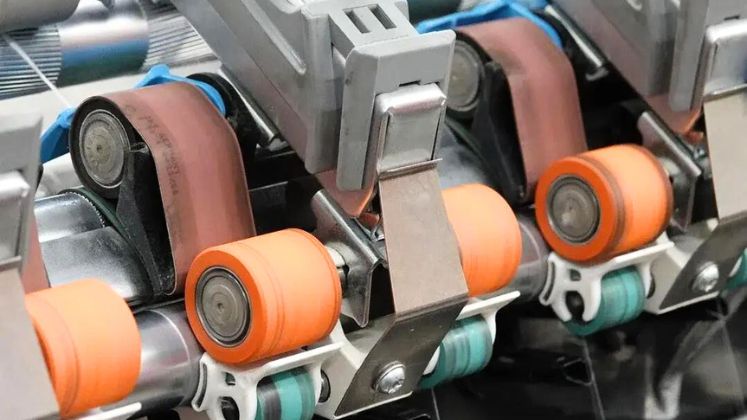

Clothes require preparation sooner than they’re usually recycled and that’s the specialty of France-based Cetia.

Cetia affords quite a lot of machines for this goal. Some are straightforward, like a machine that yanks the soles off sneakers, whereas others are further superior, akin to an AI-powered machine that identifies onerous elements like buttons and zippers and makes use of a laser to remove them with out damaging the garment.

Cetia’s use of AI and laser experience represents an enormous innovation throughout the textile recycling enterprise. The combination minimises waste and preserves the integrity of the recyclable supplies.