Shree Renga Polymers received right here into limelight in 2023 when Prime Minister Narendra Modi wore a Blue Sadri Jacket made of material recycled from PET bottles throughout the Parliament, which instantly grew to turn out to be viral. The jacket was produced by Ecoline Garments, a sustainable vogue mannequin of Shree Renga Polymers, a frontrunner in pet bottle recycling and sustainable textiles in India.

“Every day, we produce as a lot as 25 tonnes of fibre involving recycling of over 30 tonnes of plastic PET bottle waste,” talked about Senthil Sankar, Proprietor, Shree Renga Polymers. Based in Karur, Tamil Nadu, the company has an annual turnover of Rs. 100-110 crore and specialises in dope-dyed colours and specialty recycled polyester fibres.

Senthil shared that as a result of the agency’s founding in 2008 by his father Okay. Sankar, they’ve developed better than 50 colours in a quick span of time and have capabilities to produce flame retardant, anti-microbial, trilobal and gap fibres. “Our Distinctive Selling Proposition is the pliability to manufacture colourants and masterbatches in-house for the dope dyed processing. We have the unmatched talent to match the precise coloration requirements of our purchasers,” he added. Pushed by his passion for polymer merchandise and inexperienced self-discipline initiatives, Okay. Sankar pursued Publish Graduate analysis in Polymer Experience on the Indian Institute of Experience, New Delhi. Over time, he gained intensive hands-on experience in a wide array of polymer merchandise, along with PET fibres, FRP merchandise, synthetic marble, plastic components for white objects and textiles, nylon compounds and PET engineering plastics. Senthil Sankar, his son, joined the family enterprise in 2011 after leaving his place at Tata Consultancy Firms, the place he labored for 3 years. As we communicate, Senthil is a worthwhile entrepreneur, industrialist and angel investor, with over 14 years of commerce experience.

In an distinctive chat with Apparel Property, Senthil reveals why going inexperienced doesn’t should interrupt the monetary establishment and walks us by his progressive enterprise course of.

AR: How do you flip discarded PET bottles into helpful merchandise whereas championing every social accountability and environmental sustainability?

SS: We have virtually 20,000 ragpickers all through Tamil Nadu, Kerala, Pondicherry, Andhra Pradesh and Karnataka involved on this effort. These ragpickers collect PET bottles from trash, events, lodging, consuming locations and totally different areas. Our suppliers purchase these bottles from the ragpickers and crush them at extreme tempo to sort flakes. These flakes then endure an in depth 10-step course of to produce clear, premium-quality PET flakes. The recycled polyester fibres that we produce using pet bottles are used as the primary aspect in producing recycled yarns. The fibres are subject to Ring Spinning Course of to remodel them into yarns. This train entails distinctive machines the place the fibres are oriented, carded and finally spun into yarns. Being dope-dyed throughout the earlier a part of manufacturing, the yarns do away with the tactic of separate dyeing at this juncture.

The Recycled Polyester Yarns we produce are of sorts along with 4s, 6s, 10s, 16s, 20s, 24s, 30s, 36s, 40s, and plenty of others. These have quite a few functions in making polyester, blended supplies, knitting, shawls, woollen provides, and plenty of others.

AR: How do you make sustainability cheap with out compromising on prime quality or elevating costs?

SS: We maintain our merchandise priced very pretty because of we cope with each little factor in-house—from recycling the bottles to creating the last word mannequin. In distinction to larger producers that provide supplies from others and add their very personal margins, we’ve mastered the art work of producing cheap, sustainable supplies.

We have proved that sustainability is possible with out the extreme price tag, nevertheless reaching this requires sturdy experience and expertise, which we’ve acquired. Not all entrepreneurs can pull this off merely, nevertheless with the proper methodology, it’s attainable. As demand for sustainable merchandise grows, prices will naturally drop as a consequence of elevated amount.

AR: As a champion of sustainability, what initiatives have you ever ever utilized to help this set off?

SS: The strategy of producing polyester from PET bottles is in itself sustainable. In distinction to the traditional methodology using virgin provides like Purified Terephthalic Acid and MEG (Monoethylene Glycol) — which releases harmful CO2 emissions—our course of is eco-friendly. By recycling PET bottles, we create a sturdy polyester materials with the subsequent intrinsic viscosity, lowering environmental impression.

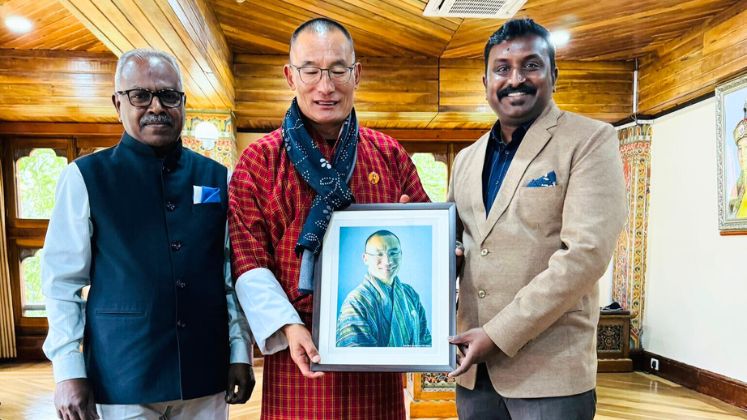

In addition to, we supply out a Life Cycle Analysis (LCA) to verify the carbon emissions of producing virgin polyester versus recycled polyester. From our analysis, we’ve found that every T-shirt we promote helps save about 4 kg of CO2 from being emitted into the atmosphere as compared with making it from virgin polyester. Equally, each ‘MODI’ jacket we produce saves over 8 kg of CO2. We’re moreover proud to be part of the Siachen enterprise, the place we rework PET bottle waste from the Siachen Glacier into sustainable Sadri jackets. The proceeds from this initiative help the native Ladakhi tribes for his or her upliftment and enchancment. This progressive thought received right here from an Army Brigadier who wanted to cope with waste administration creatively and we teamed as a lot as make it happen.

The army handles the crushing of these bottles in Ladakh after which sends the flakes to us. We recycle these flakes into jackets and ship them once more to Ladakh.

Since launching our D2C sustainable mannequin, Ecoline Garments, in 2021, we’re offering a wide range of newest designs for males, women and children, along with casualwear, sportswear, nightwear, winterwear and coats. We’re moreover doing correctly throughout the firm part by offering customised, sustainable corporatewear and we provide CO2 and water monetary financial savings certificates to our purchasers.

We’re moreover licensed by GRS, TUV SUD, OEKO-TEX, Ocean Positive Plastic and ZED.

AR: What thrilling new enhancements have you ever ever been engaged on today?

SS: Innovation drives us and we’re constantly pushing the envelope. Every month, we preserve ‘Innovation Meet-ups’ the place we dive into new ideas and methods to take care of our mannequin predominant the way in which wherein. We’re not almost sustaining; we’re about breaking new ground.

Take, as an illustration, our latest initiatives: we’ve started turning PET bottle caps and rings into vegetable trays—stuff that can in another case go to waste. We’re moreover creating bricks from sludge discarded by our Effluent Remedy Plant, mixing it with mud, paper and specific growth provides. We’re recycling ash from our picket fireplace boiler and using recycled water from our plant to make these bricks far more sustainable. On excessive of that, we’re diving into biodegradable polyester and experimenting with plant-based and bacteria-based dyeing for our pure cotton merchandise. We’re all about discovering new strategies to make our processes greener and additional atmosphere pleasant.

We have virtually 20,000 ragpickers all through Tamil Nadu, Kerala, Pondicherry, Andhra Pradesh and Karnataka involved on this effort. These ragpickers collect PET bottles from trash, events, lodging, consuming locations and totally different areas.