Worldwide consciousness about sustainability is rising, and although progress is sluggish, it is steadily gaining momentum. The textile commerce, as a critical polluter with its full present chain, is now most important the best way wherein in prioritising sustainability—adopting eco-friendly provides, lowering waste and minimising carbon footprint. This progress is particularly important as spherical 70 per cent of pattern commerce emissions stem from upstream actions like supplies manufacturing and processing. These efforts are reworking manufacturing practices and reshaping every shopper expectations and market tendencies.

As a result of the commerce steps up its efforts, the federal authorities could be stepping in to provide assist by means of insurance coverage insurance policies that encourage sustainable practices.

After years of focus on with out follow-through, the Centre is now taking concrete steps by preparing a framework on sustainability for the textile commerce with clear deliverables. This framework, being prepared in session with the commerce, will set short-term and long-term sustainability targets for the sector.

The occasion comes as western nations’ such as a result of the US, UK and European nations’ have enacted quite a few authorized tips on sustainability. For example, the European Union has already launched its ‘EU Method for Sustainable and Spherical Textiles’, which evokes all textile merchandise purchased all through the EU’s 27 member nations to be sturdy, repairable, recyclable, largely created from recycled fibres, free of hazardous substances and produced in methods wherein respect social rights and the environment.

Turning Waste into Price

With the textile commerce accountable for 1.2 billion tonnes of greenhouse gasoline emissions and US $ 500 billion in losses from under-recycled garments yearly, consultants argue that adopting sustainability measures might unlock a US $ 500 billion market and create very important price.

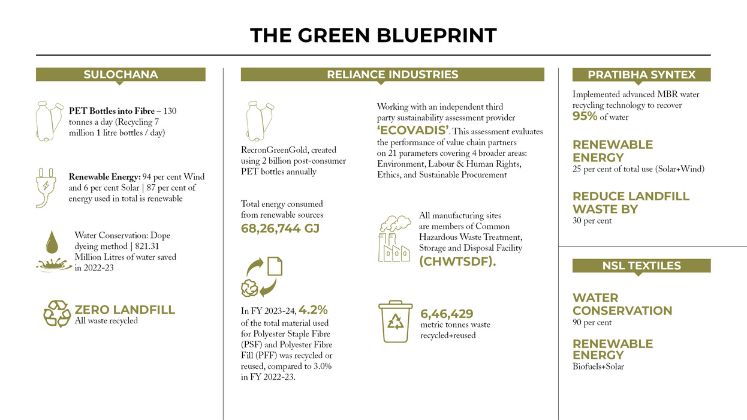

“We’ve now already scaled our recycled fibre capacities. Presently we produce 130 tonnes of recycled polyester fibre and eight tonnes of recycled cotton fibre,” revealed R. Sabhari Girish, Head of Sustainability, Sulochana Cotton Spinning Mills. The company claims to be an important producer of melange/marl yarn in India with an put in functionality of 120,000 spindles and 50 tonnes of melange yarn per day. It claims to utilize GRS-certified Recycled Yarn and all its merchandise are made using 100 per cent post-consumer PET bottles, nevertheless as a result of the caps are manufactured from polypropylene, which can’t be was fibre, they’re instead processed into pellets. These pellets are then offered to industries that make plastic merchandise. Equally, labels created from PVC (polyvinyl chloride) are eradicated and despatched to the cement commerce, the place they’re used to generate electrical power.

In step with Girish, “Recycled yarn is normally made using Open End Spinning. Nonetheless, six years previously, Sulochana carried out evaluation and progress to spin recycled yarn using Ring Spinning, resulting in increased hand-feel and bigger pilling resistance. Presently, we’re ready to spin as a lot as 34s with 100 per cent sustainable supplies (60 per cent Recycled Cotton/40 per cent Recycled Polyester). Our latest achievement is that our preliminary bulk manufacturing has confirmed we’re capable of now spin as a lot as 40s with 100 per cent recycled supplies.”

He outlined that the company primarily works with producers to point out their post-industrial waste into yarn, materials or garments, based mostly totally on the producers’ needs. The producers be a part of them with their vendor factories to assemble the waste and they also put together the factories’ chopping rooms to sort the waste by coloration and top quality. This way, most of the waste (about 98 per cent) is already sorted when it arrives. The producers actually have a good suggestion of what waste may be on the market, almost a season prematurely, which helps them plan their varieties early. For example, for Spring/Summer season 2025, they use waste from Fall/Winter 2024. This course of helps create a spherical story for the producers, as they bring about about their very personal waste once more into their present chain.

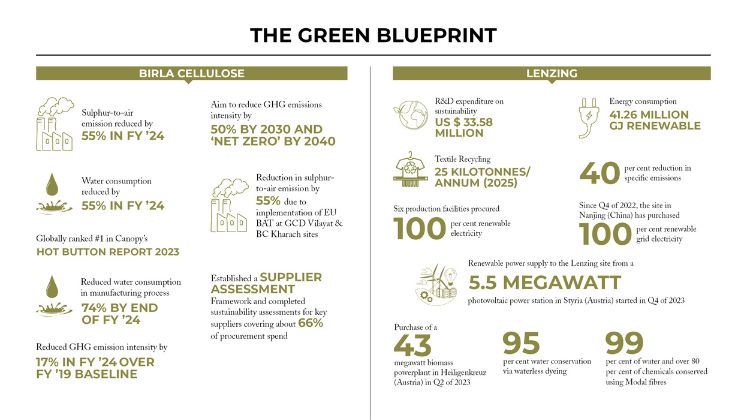

“Innovation has always been the core of Birla Cellulose and now now we have proved our mark with launch of newest revolutionary fibres like Livaeco, Liva Reviva, purposeful viscose fibres like Birla SaFR and Birla Intellicolor viscose. Liva Reviva mannequin overarches our spherical fibre product basket and it has been a specific innovation as a result of it focuses on utilising textile waste once more as feed stock and throughout the course of, there are a variety of various belongings’ low cost. We started with 20 per cent waste, now now we have now launched the fibre with 30 per cent textile waste,” talked about ManMohan Singh, CMO – Birla Cellulose, Grasim Industries Ltd.

He moreover confused that over 110 producers and over 2000 price chain collaborators worldwide are presently using Birla Cellulose’s GreenTrack™ traceability platform which leverages blockchain experience to supply producers with real-time insights into the journey of raw provides from forest to retail retailer.

Echoing comparable sentiment, Rakesh Bali, Sr. VP and Head of Promoting and advertising and marketing – PetChem Enterprise, Reliance Industries, an important producer of polyester fibre and yarn on this planet, with a functionality of two.5 million tonnes yearly, shared, “We presently recycle over 2 billion post-consumer PET bottles yearly and objective to larger than double this to over 5 billion bottles. This initiative produces Recron GreenGold, one in every of many world’s most sustainable fibres, utilized in manufacturing R|Elan GreenGold supplies.”

Sharing his concepts, Bhavik Shah, BDM – Producers and Firm, Wonderful Filaments Restricted conveyed, “There’s an ample present of raw provides, due to years of amassed recyclables — provides that had been as quickly as discarded nevertheless can now be repurposed and reused.” Wonderful Filaments is a vertically built-in manufacturing facility, specialising throughout the manufacturing of polyester textured yarns, from chips to textured yarn, with coloration doping capabilities on 100 per cent POY traces and Explicit Double Density DTY machines.

The company moreover makes use of CiCLO experience, a sustainable textiles ingredient inside the kind of an additive that is combined with polyester and nylon all through soften extrusion on the very beginning of the fibre making course of. CiCLO additive creates quite a few biodegradable spots throughout the matrix of the plastic, the place microbes that naturally exist in positive environments can break down the provides equivalent to they do with pure fibres. The chemistry used to create CiCLO fibres is ECO PASSPORT licensed by OEKO-TEX.

Equally, NSL Textiles, part of the US $ 1 billion conglomerate NSL Group with pursuits in seeds, infrastructure, power, sugar and textiles, is charting a course for a closed-loop and spherical manufacturing system to minimise waste.

“We give consideration to recycling textile waste generated all through manufacturing, along with materials scraps, off-cuts and post-consumer waste. Over the next three years, we objective to increase our recycling efforts, specializing in a 20 per cent to 30 per cent low cost in waste. This may be achieved by growing recycling capabilities and bettering sorting utilized sciences,” commented Pritam Das, Sr. Govt Compliance, NSL Textiles Ltd. The daddy or mom agency, Nuzeevidu Seeds Restricted, is an important seed agency in India.

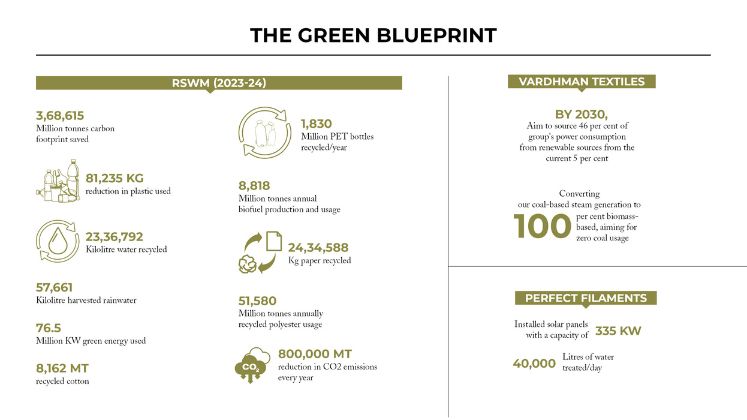

Addressing the plastic waste catastrophe, RSWM, the flagship agency of LNJ Bhilwara Group with an internet worth of US $ 1.2 billion and one in every of many most important producers and exporters of synthetic, cotton and blended spun yarns in India, recycles roughly 1,830 million PET bottles yearly, altering them into 51850 MT of recycled polyester fibre. This helps save 368,615.88 MT of carbon emissions.

Fibre inexperienced® by RSWM, created from recycled PET bottles, provides a sustainable decision by means of recycled polyester fibre, which fastidiously resembles virgin polyester. This product might be blended with various fibres to create yarns for consumer-grade supplies.

| Since 2023, now now we have partnered with Swedish pulp producer Södra to develop recycling of textile waste on an industrial scale, contributing our knowhow in REFIRBA™ experience to permit various difficult, coloured textiles.S. Jayaraman VP of Worldwide Product sales Textiles, Lenzing |

“From alternatives on whether or not or to not discard or reuse, we attempt to embed sustainability into every aspect of our enterprise. Allocating devoted budgets for sustainability inside our annual plans is a priority for us,” declared BM Sharma, Jt. MD, RSWM Ltd. The company yearly produces 1,21,000 MT Greige Yarn, 24,000 MT Melange yarn, 32,000 MT Dyed yarn, 32 Metres Denim Material, 9000+ MT Knits Material and 43,000 MT Inexperienced Fibre.

“Our closed-loop manufacturing in spinning integrates textile waste once more into our merchandise, lowering landfill waste by roughly 30 per cent,” claimed Mukesh Matta, Head of ESG and Sustainability Initiatives, Pratibha Syntex. The company has 4 verticals along with farming, yarn, materials and garmenting.

The REFIBRA™ experience from Lenzing focuses on rising the recycled content material materials in fibres by upcycling cotton scraps from pre- and post-consumer textile waste. These scraps are remodeled into recycled pulp, with 30 per cent blended with wood pulp to create new virgin TENCEL™ Lyocell fibres.

“Since 2023, now now we have partnered with Swedish pulp producer Södra to develop recycling of textile waste on an industrial scale, contributing our knowhow in REFIRBA™ experience to permit various difficult, coloured textiles containing a mixture of cotton, polyester and totally different components along with elastane to be processed and recycled in future,” averred S. Jayaraman, VP of Worldwide Product sales Textiles, Lenzing.

Headquartered in Austria, Lenzing group offers the worldwide textile and nonwoven commerce with man-made cellulose fibres manufactured from sustainable sources corresponding to wood and wood pulp.

The company moreover applies closed-loop manufacturing strategies. For example, Lenzing’s Lyocell course of recovers 99.8 per cent of the NMMO solvent required, which is then fed once more into the strategy. In a single different case, the place worthwhile raw provides are extracted from wood for pulp manufacturing, the rest of the provides could be utilized to generate bio-refinery merchandise corresponding to acetic acid, thermal vitality and electrical power. Due to this course of, the company’s vegetation in Paskov (Czech Republic) and Indianópolis (Brazil) hardly require the additional purchase of vitality for pulp manufacturing.

Vardhman has established Vardhman ReNova, a cotton recycling facility with a six TPD manufacturing functionality. “This enterprise takes an enormous stride on this course by recycling every pre- and post-consumer waste into high-quality yarn,” talked about Mukesh Bansal, Head (Material Promoting and advertising and marketing), Vardhman Textiles Restricted, a primary vertically built-in textile producer with a producing functionality of 670 metric tonnes of yarn per day, 180 million metres of fabric per yr and 22,000 metric tonnes of fibre yearly.

Inexperienced Energy, Water Conservation and Blocking Toxins

Commerce leaders are embracing renewable vitality by chopping down on fossil fuels and investing in sustainable power sources. Many firms are giving extra thrust to harness wind power and adopting biofuels corresponding to rice husk, maize shank and biomass to power their operations.

As an illustration, Wonderful Filaments has put in picture voltaic panels with a functionality of 335 KW and is planning to place in ore.

At Sulochana’s essential plant, 100 per cent of the vitality used comes from renewable sources, with 94 per cent from wind and 6 per cent from picture voltaic. The picture voltaic panels are moreover manufactured on-site. All through all their fashions, roughly 87 per cent of the vitality consumed is from renewable sources.

Likewise, NSL Textiles targets to transition to 100 per cent picture voltaic vitality for all frequent vitality needs all through its operations inside the next 5 years. It moreover makes use of biofuels created from 100 per cent rice husk in its operations and is exploring utilizing maize shank as an extra biofuel provide to extra diversify its vitality present.

RSWM has moreover put in Photograph voltaic Vitality Vegetation at its various manufacturing locations along with Kanyakheri, Mandpam, Gulabpura, Kharigram, Mordi, Ringas and Rishabdev.

Lenzing is tapping into bioenergy by means of the acquisition of a 43-megawatt biomass power plant in Austria, which could help substitute 50 per cent of pure gasoline used at its Lyocell plant, lowering CO2 emissions of the plant by spherical 50,000 tonnes per yr.

“We’ve now been growing our inexperienced electrical power mix in our fibre and pulp manufacturing. On the Lenzing web site in Austria, now now we have been producing picture voltaic vitality and making purchase agreements to provide further renewable electrical power,” talked about Krishna Manda, VP, Firm Sustainability, Lenzing.

With the garment and textile commerce consuming about 79 trillion litres of water yearly — ample to meet the needs of 27 per cent of the worldwide inhabitants based mostly on WHO necessities — very important efforts are moreover underway to chop again this extreme diploma of water utilization. Producers are leveraging experience to develop revolutionary strategies to save lots of a lot of water.

For example, NSL Textiles’ Air-Dye® experience makes use of compressed air and heat instead of water to change dye onto materials. This course of eliminates the need for large parts of water.

As a primary viscose producer, Birla Cellulose claims their water consumption in making 1 kg of viscose fibre is lowest and it moreover benefits in decreasing carbon footprint.

“Our EcoD utilises an eco-friendly dyeing course of by which coloration is built-in instantly into the polymer, eliminating the need for standard water-intensive dyeing methods. EcoD moreover consumes solely one-tenth of the vitality required for traditional dyeing and avoids Class-A pollutant dyestuffs,” remarked Rakesh Bali.

The commerce avid gamers are moreover using low-temperature dyeing processes, which require a lot much less vitality and fewer harsh chemical substances, main to every lowered chemical waste and water utilization. Moreover they prioritise utilizing pure dyes and eco-friendly chemical choices.

With the introduction of dope-dyed fibres with Indigo Colour experience, Lenzing has significantly lowered water consumption by over 99 per cent. This experience incorporates indigo pigment instantly into TENCEL™ branded modal fibres by means of a one-step spun-dyeing course of, serving to ensure water conservation all by your whole product lifecycle.

The company has moreover partnered with Exponent Envirotech to implement waterless dyeing experience for cellulose fibres, significantly for Cobalt Vogue’s knitwear assortment. This system saves as a lot as 95 per cent water, reduces dyestuff and vitality use and eliminates salt, serving to to take care of the commerce’s ongoing topic of extreme salinity in wastewater.

Commerce avid gamers moreover ask their suppliers to watch ZDHC Manufacturing Restricted Substance Guidelines (MRSL) of their course of.

Sustainability’s Roadblocks: The Path Isn’t Easy

As organisations try and stability improvement with environmental accountability, they face very important challenges alongside the best way wherein. Rakesh Bali recognized that to begin with, the house textile commerce confronted very important challenges attributable to an oversupply of supplies and apparel imported from China amidst lower export demand from key markets identical to the US and EU. These imports, normally undervalued and misdeclared, disrupted the house textile present chain and affected income margins. Due to this, the polyester commerce operated at decrease than 70 per cent functionality.

Important capital and technical expertise are required for the downstream textile price chain to spend cash on new utilized sciences geared towards enhancing manufacturing effectivity and lowering environmental impression. Skills shortage is one different massive drawback. Equally important is to show prospects about the benefits of sustainable merchandise and to dispell misconceptions to drive demand and encourage accountable consumption.

“Although the demand of sustainable viscose fibre has seen improvement season after season, nevertheless the volumes are very small as producers are unable to cross the price. With shopper consciousness within the route of sustainable offering ,we anticipate that, over time, demand of sustainable viscose fibre will enhance resulting in bigger adoption of such supplies by price chain companions along with spherical fibre Liva Reviva,” expressed ManMohan Singh.

Some producers are moreover going by functionality challenges, as an illustration, NSL Textiles Ltd., has really seen a sturdy curiosity in 100 per cent pure cotton. Whereas this supplies is in extreme demand attributable to its eco-friendly properties, they’re nonetheless going by some functionality challenges.

“The essential factor drawback comes from the higher price degree of pure cotton compared with commonplace cotton, which can make it more durable to scale manufacturing shortly. The related price is pushed by parts like lower yields per acre, the need for specialised farming practices and the certification course of that ensures it’s actually pure,” well-known Pritam Das.

Within the meantime, others are ramping up their operations to meet rising demand. Lenzing has invested larger than € 200 million in its manufacturing web sites since 2021, altering present functionality for generic viscose into functionality for specialty fibres. Jayaraman well-known, “Up to now, now now we have ramped up our Lyocell manufacturing functionality by almost 40 per cent and boosted our Modal manufacturing by spherical 30 per cent. In sustainable viscose, now now we have larger than doubled our specialty fibre capacities, making us well-prepared to meet shopper demand.”

Birla Cellulose plans functionality ahead of demand by means of brownfield duties and debottlenecking alternate options of present functionality and might proceed to care for the equivalent principle for all their future expansions.

One different drawback producers face is that customers anticipate recycled merchandise to match the usual and coloration consistency of virgin provides. Bhavik urged producers to determine distinct top quality and colour-matching necessities significantly for recycled merchandise, aligning with sustainability targets. “As an illustration, if producers had been to allow a barely bigger tolerance for coloration variations, we might reduce the need for repeated dyeing processes, thereby conserving pure belongings,” he acknowledged.

Girish highlighted that it’s robust to sort fibres persistently on an enormous scale, which signifies that the fibre content material materials in recycled supplies can fluctuate extensively. For example, one a part of materials might embrace 70 per cent polyester, 20 per cent cotton, 5 per cent viscose, 3 per cent acrylic and a few per cent unidentified fibres, nevertheless only some metres later, the combination might shift to 65 per cent polyester, 15 per cent cotton, 15 per cent viscose, 4 per cent acrylic and 1 per cent unidentified fibres.

| The house textile commerce confronted very important challenges attributable to an oversupply of supplies and apparel imported from China amidst lower export demand from key markets identical to the US and EU. These imports, normally undervalued and misdeclared, disrupted the house textile present chain and affected income margins. Rakesh Bali Sr. VP and Head of Promoting and advertising and marketing, PetChem Enterprise |

This inconsistency makes mechanical recycling of post-consumer textile waste troublesome. In distinction, recycling post-industrial waste—primarily the cutoffs from apparel manufacturing—is much less difficult.

Specialists moreover recognized that customers are nonetheless hesitant to pay the premium for sustainable merchandise.

“As a result of the purchasers have gotten further environmentally and sustainability conscious, they’re an increasing number of ready to pay a premium for sustainable merchandise. Nonetheless, price sensitivity stays a key challenge. Producers and retailers ought to stability premium pricing with the price proposition of sustainability, specializing in top quality, effectivity and ethical sourcing to justify bigger costs,” proposed Rakesh Bali.

Reinforcing the attitude, Mukesh Bansal asserted, “The willingness of shoppers to pay a premium varies all through completely totally different market segments. We’ve now seen {that a} good portion of our prospects, significantly these throughout the premium and opulent segments, are ready to spend cash on sustainable merchandise, recognising the long-term benefits and ethical implications.”

An rising perspective throughout the commerce implies that meeting the demand for sustainable merchandise does not stem from a shortage of belongings or provides—considerably in India, the place sustainable dyes, chemical substances and fibres can be found for these dedicated to sourcing them. In its place, the primary challenges normally lie in guaranteeing that every part of the supply chain persistently adopts these sustainable selections.

| The Inexperienced Revolution in Trims and Gear

As a result of the dialog spherical sustainable present chains picks up, the often-overlooked sector of Indian trims and tools is shortly making sustainability a first-rate priority. Titan Zip Fastener Industries, as an example, has been using pressurised pure gasoline (PNG) since 2012 and ensures its merchandise are free from battle minerals like titanium, tin, tungsten and gold. Madeira makes use of 80 per cent recycled water and incorporates sustainable provides corresponding to recycled polyester and Sensa Inexperienced (Lyocell) in its merchandise. Equally, Telephone Thread is prioritising sustainability by means of technological upgrades, corresponding to using a gas-based boiler in its dyeing plant, implementing rainwater harvesting and dealing its Delhi office on photo voltaic power and LED lighting. The company moreover launched an surroundings pleasant Swiss-made Thread Winding Machine to boost product effectivity. Vardhman Yarns & Threads Ltd., has launched quite a few revolutionary sustainable merchandise, along with the world’s first anti-counterfeiting, sustainable stitching thread known as INTEGRITY, developed in partnership with Utilized DNA Sciences. This molecularly tagged thread ensures authenticity and offers a solution for sustainable traceability. Completely different firms are moreover making strides in sustainability. As an illustration, Ketan Buttons Pvt. Ltd., produces eco-friendly buttons created from repurposed horn, corozo (tagua palm seeds) and coconut shells. Kotak Group is exploring utilizing high-quality recycled plastic bones. For his or her Japanese shoppers, along with Daiso, they’re producing hangers created from sustainable provides, utilising patented polymer experience that comes with TANTEC polymers, which emit fewer emissions when burned. |